Dow Corning Sealants

Product Details:

- Purity 92%

- Color White

- Physical State Liquid

- Click to view more

Dow Corning Sealants Price And Quantity

- 398 INR/Unit

- 1 Unit

Dow Corning Sealants Product Specifications

- 92%

- White

- Liquid

Dow Corning Sealants Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 5-10 Unit Per Month

- 4-6 Week

- No

- All India

Product Description

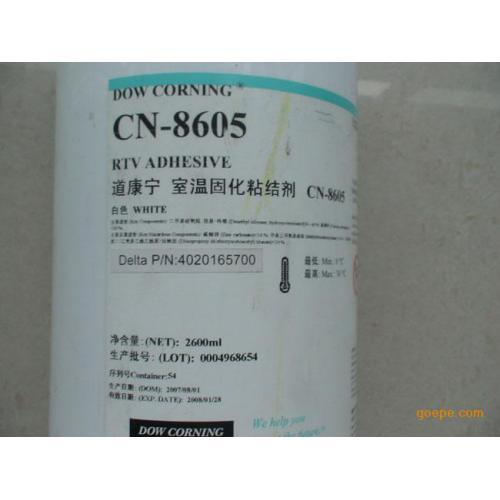

CN-8605

Dow Corning one-part moisture cure adhesives are generally cured at room temperature and in an environment of 30 to 80 percent relative humidity eliminating the need for curing ovens and the associated costs of energy and capital. Greater than 90 percent of full physical properties should be attained within 24 to 72 hours and varies according to product. Faster manufacturing throughput is achieve however since the adhesive and component can be handled in much shorter times of about 10 to 120 minutes depending on the adhesive selected and the amount of applied. These adhesives are not typically used in highly confined spaces or where a deep section cure is required as they generally cure from the exposed surface inward at a rate of 0.25 inch per seven days. Cure progresses from the outer exposed surface and is dependent on the moisture in the air. Working time is generally a few minutes to an hour for these products until a surface skin begins to form. Mild heat below 60C (140F) may be used to increase through-put by accelerating the cure. Dow Corning silicone adhesives retain their original physical and electrical properties over a broad range of operating conditions which enhance the reliability of and service life of electronic devices. The stable chemistry and versatile processing options of these adhesives offer benefits for a variety of electronics needs from increasing component safety and reliability, reducing total cost or increasing the performance envelope of devices or modules.

FEATURES

- No corrosive cure by-products

- Low volatility

- UL 94V-0

BENEFITS

- One part for easy and fast dispensing

- Fast skin-over time for quick handling and reduced cycle time

- Neutral cure for use around all electrical and electronic devices

POTENTIAL USES

- Component fixing and attaching

- Device sealing

APPLICATION METHODS

- Manual or automated needle dispense

One-part, white, semi-flowable room temperature curing silicone adhesive

TYPICAL PROPERTIES Specification Writers: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product. Property Unit Value Viscosity cP mPa-sec Pa-sec 53000 53000 53

Specific Gravity (Cured) - 1.59

Skin Over Time at 25 C minutes 8

Tensile Strength

psi MPa kg/cm2

320 2.2 22

Elongation % 120

Durometer Shore A - 50

Unprimed Adhesion - Lap Shear to Aluminum

psi MPa kg/cm2

250 1.7 17

Dielectric Strength

volts/mil kV/mm

600 24

Volume Resistivity ohm*cm 3.32 E+16

Dielectric Constant at 100 Hz - 4

Dielectric Constant at 100 kHz - 3.2

Dissipation Factor at 100 hz - <0.1

Dissipation Factor at 100 kHz - <0.1

Content of Low Molecular Siloxane (D4-D10)

ppm 300

UL Flammability Classification NA 94V-0

Shelf Life at 25 C months 6